Green hydrogen is reshaping energy-intensive industries by serving as a clean and sustainable feedstock for chemical production, refining, and advanced materials. Beyond feedstock, it provides a zero-carbon heat source for high-temperature processes, offering sectors such as chemicals, glass, ceramics, and metals a reliable pathway to deep decarbonisation. It also powers breakthrough industrial processes like Direct Reduced Iron (DRI), enabling large-scale green steel production.

By replacing fossil fuels across feedstock, heat, and process applications, green hydrogen helps industries cut emissions, comply with regulations, and strengthen their competitiveness — all while driving a cleaner, greener future. The future of hydrogen is green. Are you ready to lead the change?

Decarbonisation Starts with Green Hydrogen

Green hydrogen presents a viable solution for achieving net-zero emissions—not only by eliminating CO₂ emissions at the point of use, but also across the entire value chain thanks to renewable-powered production.

It enables industries to replace fossil fuels in high-temperature processes, serves as a carbon-free feedstock for chemical production, and supports operations where traditional fuels are currently indispensable. By switching to green hydrogen, companies can cut emissions, reduce reliance on imported fossil fuels, achieve energy independence through local production, and maintain performance without compromise. In fact, green hydrogen can deliver up to ten times greater CO₂ reductions compared to conventional alternatives — while turning the challenge of carbon taxes and rising compliance costs into a competitive advantage.

A Key Driver for Net-Zero Industry:

- Eliminates CO₂ emissions at the point of use

- Enables deep decarbonisation of high-heat industrial processes

- Provides a renewable feedstock for chemicals and other industrial applications

- Supports continuous, reliable operations powered by renewables

- Reduces dependence on fossil fuels, enhancing energy security

- Generates energy independence and supports local production

- Achieves up to 10x greater CO2 reduction potential

- Turns carbon taxes into a driver of competitiveness

- Aligns with national and international climate targets

Green hydrogen isn’t just an alternative — it’s essential for decarbonising heavy industry at scale.

Why choose renewable and green hydrogen?

Reduce CO2 Emissions

Cut emissions at the point of use and across the value chain by replacing fossil fuels with renewable hydrogen.

High-Temperature Process Compatibility

Decarbonise processes where electrification isn’t feasible, from steel and cement to chemical production.

Control Costs

Mitigate exposure to fossil fuel price volatility and manage energy-related costs using flexibility mechanisms and costs tied to CO2 emissions.

High Purity

Green hydrogen offers the advantage of being produced at very high purity levels. This makes it especially valuable for electronics, controlled atmospheres, speciality chemicals and other processes where even trace impurities cannot be tolerated.

Energy Flexibility & Reliability

Hydrogen acts as both fuel and energy storage, decoupling generation from consumption and aiding grid stability.

Competitive Advantage

Adopting hydrogen as a clean energy source helps organisations stand out, reach ESG objectives, attract sustainability-minded stakeholders, and strengthen their market position.

Stable and Secure

Hydrogen provides a stable and reliable energy source with predictable pricing, ensuring consistent availability. Secure long-term benefits through greater control, resilience, and confidence in your energy strategy.

3 key advantages of Lhyfe’s green hydrogen offer

Pioneer in France

We produce certified green hydrogen in France, fully compliant with RFNBO (Renewable Fuels of Non-Biological Origin) standards. As an early leader in the field, we are committed to supporting the decarbonisation of industry and mobility through clean, reliable hydrogen solutions.

Immediate Availability

Green hydrogen is available for immediate delivery across 7 countries in Europe, ensuring a consistent molecule supply to match your operational demands. Backed by 4 years of proven operations, our logistics network is optimised for efficiency, enabling seamless integration into your energy systems without delay.

Premium Delivery Solutions

We provide all delivery options to match your operational needs – from high-performance containers (300 to 380 bar pressure, with capacities from 350 kg to 1,000 kg) to onsite hydrogen production units with pipeline supply for larger volumes. With the biggest fleet in France (70 trailers) and the most efficient technology, all delivery options are designed for safety, reliability, and continuous operations.

The industrial uses of hydrogen

Explore the Application of Hydrogen Across Industries

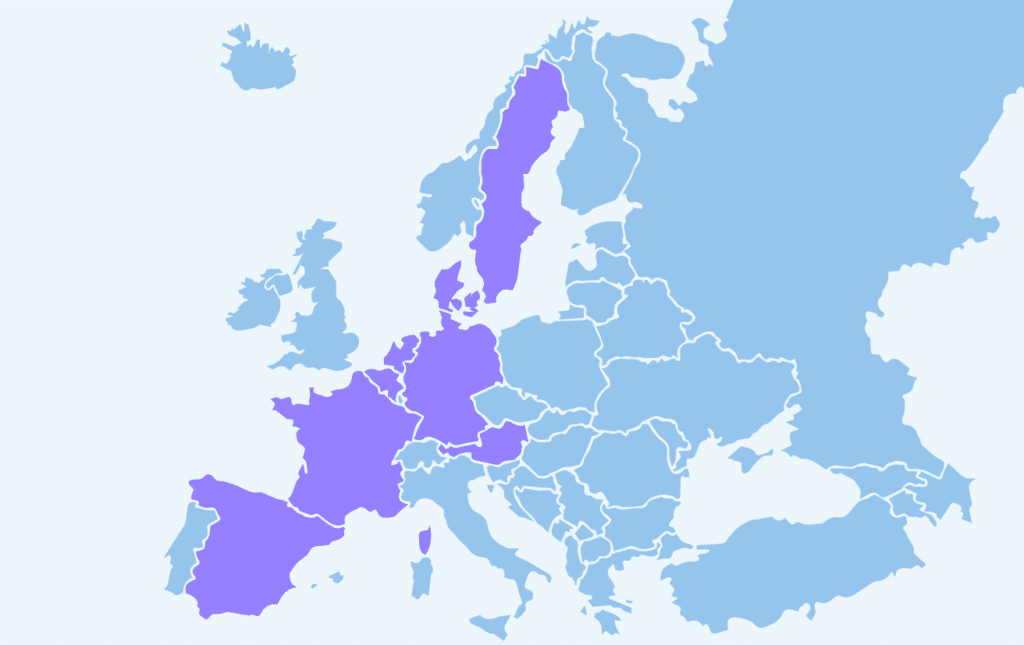

Our Hydrogen Delivery Solutions

Bulk delivery

We produce and deliver green hydrogen at scale, right to your doorstep, using high-performance containers operating at 300–350 bar pressure with capacities from 380 kg to 1,000 kg, engineered for efficiency in demanding applications. Real-time telemetry enables precise monitoring and optimised routing, ensuring reliable, high-performance delivery across the entire supply chain.

Our logistics network spans key European regions, including France, Germany, the Benelux, Spain, Sweden, Denmark, and Austria.

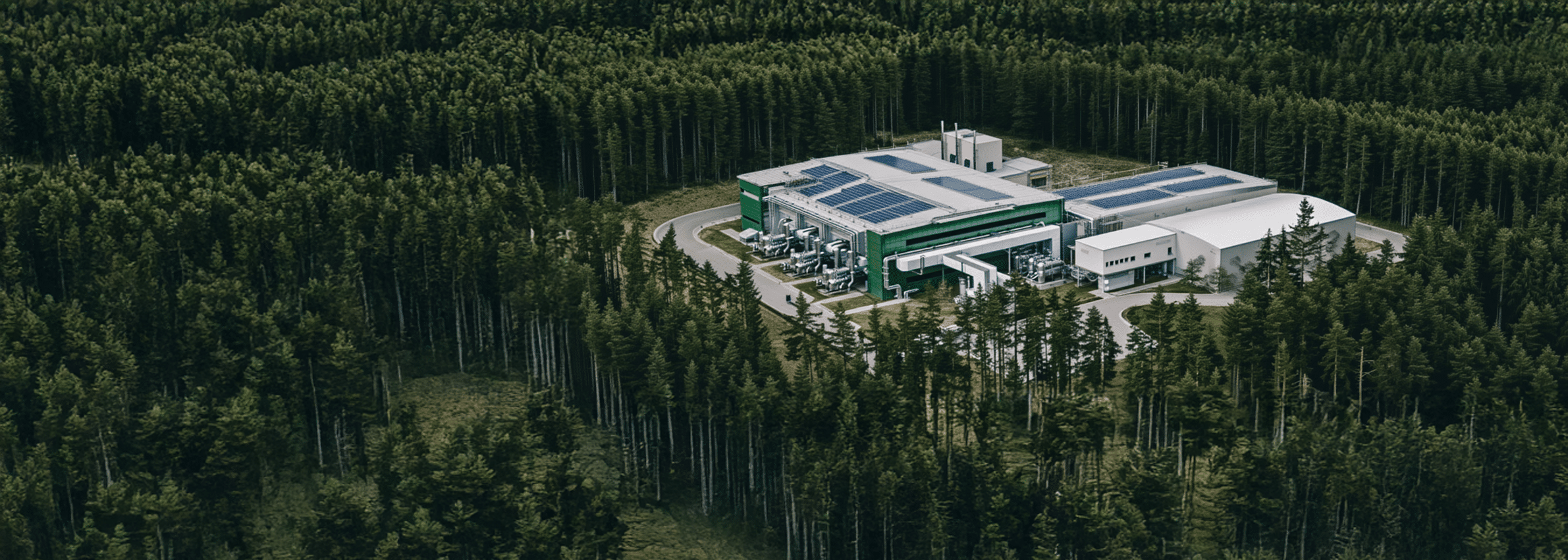

Pipeline & On-site Supply

For large and continuous hydrogen requirements (from 2 tons/day), we design, build, and operate hydrogen production units directly at your site or close to your facilities. These are paired with secure pipeline connections, ensuring uninterrupted supply and seamless integration into your processes.

This approach eliminates transport constraints and delivers the highest level of operational reliability.

3 Key Advantages of Developing a Hydrogen Project with Lhyfe

At Lhyfe, we’re with you every step of the way — from initial planning to day-to-day operations — to ensure the success of your hydrogen project. With 4 years of operational experience and X tonnes of green hydrogen supplied, we bring unmatched expertise as pioneers in production and distribution. Together, we turn your vision into a sustainable and fully operational reality.

1. Expert Access – Leverage our specialised network covering hydrogen production, storage, safety, and integration with industrial processes. Backed by Lhyfe’s proven expertise in green hydrogen, we deliver integrated, end-to-end solutions across the entire value chain.

2. Support with Subsidies and Funding – We actively assist industrial operators and project developers in securing public funding and navigating administrative processes to make projects financially viable.

3. Tailored Supply Solutions – From bulk deliveries to onsite production and pipeline connections, we design supply systems that match your specific volume, reliability, and integration needs — ensuring uninterrupted operations and long-term sustainability.

Related Content You Might be Interested in

Article

Published the 27/07/2022

Industry decarbonisation: the importance of renewable hydrogen

Although there has been much talk recently about hydrogen vehicles – as they offer a real solution for carbon-free mobility – hydrogen has nonetheless been used in industry for decades, such as to fuel furnaces, in chemical processes and refining, and even to launch rockets into space.

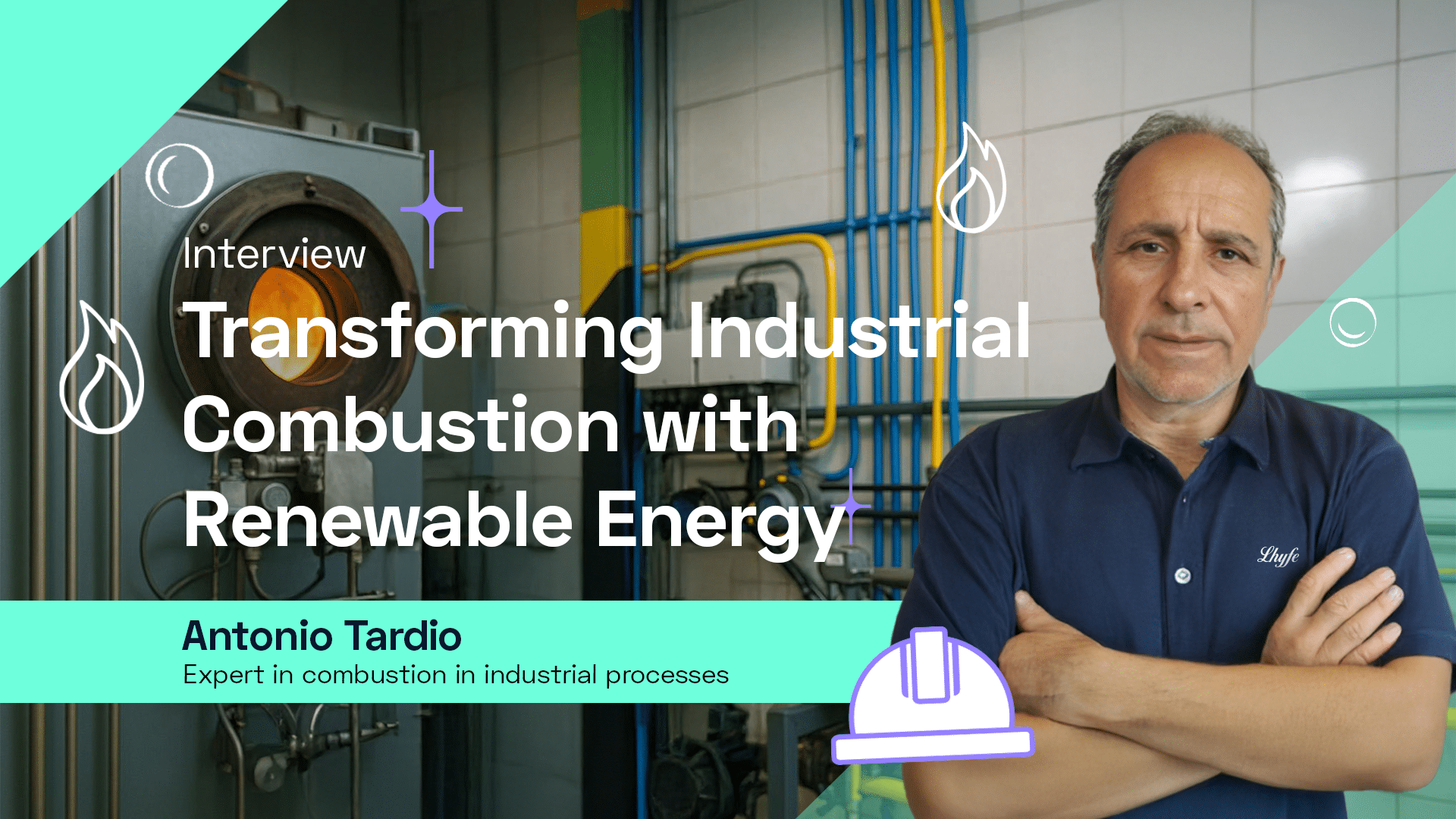

Press release

Lhyfe successfully completes first combustion tests using green hydrogen as a replacement for natural gas in the industrial sector

This first experiment, successfully deployed in the ceramics sector, can now be replicated in other sectors using combustion, thanks to the mixing kit developed by Lhyfe.