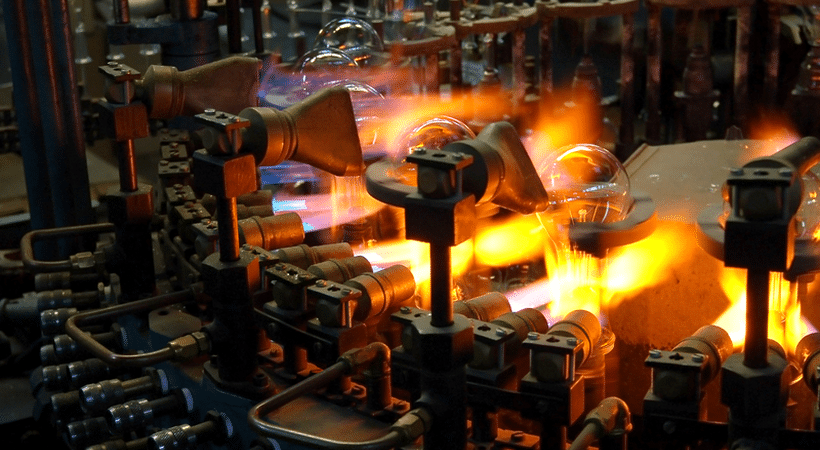

The glass industry, known for its energy-intensive processes and reliance on high-temperature combustion, faces a unique challenge in decarbonisation. While electrification is viable for some sectors, it is not always an option in glass manufacturing, where direct flames are essential for specific processes. This is where green hydrogen provides a powerful, ready-to-implement solution.

From Grey to Green Hydrogen: A Seamless Transition

Many glass manufacturers already use hydrogen today—often grey hydrogen, used in a protective atmosphere. Replacing this with green hydrogen presents no technical barriers. At Lhyfe, we have proven that switching to green hydrogen can be done without modifying core industrial infrastructure.

Have questions or need more information?

Talk to our experts

Hydrogen applications in the glass industry

Hydrogen serves as a heat source for industrial operations

Hydrogen plays a role within manufacturing processes

Flame-Based Combustion That’s Cleaner and Smarter

In cases where electric furnaces cannot meet process requirements, hydrogen and biogas (such as biomethane) provide viable alternatives to fossil fuels. Hydrogen combustion delivers the high temperatures and direct flames required in glass production, but without the carbon emissions of natural gas.

Multiple Combustion Options to Suit Every Configuration

Depending on plant configuration and objectives, several combustion approaches can be used, each offering different benefits:

- Hydrogen Combustion: A 100% green option with zero CO₂ emissions, suitable where full decarbonisation is the goal.

- Hydrogen/Natural Gas Blending: A transitional solution allowing gradual decarbonisation. This mix enables high flexibility and full reliability to target an optimised cost of production.

- Oxy-Combustion with Hydrogen: By using pure oxygen instead of air, this method requires less fuel, reduces smoke emissions, and improves flame control. It also facilitates heat recovery and flue gas purification.

Whichever method is chosen, combustion control systems remain largely unchanged, making it easier for operators to manage the process without extensive retraining or system overhaul.

Proven Expertise and Industry Partnerships

Lhyfe has conducted successful hydrogen combustion trials in energy-intensive sectors such as ceramics and metallurgy, demonstrating the reliability and effectiveness of green hydrogen under real industrial conditions.

Support Through Carbon Regulations and Incentives

Thanks to environmental policies such as the EU Emissions Trading System (ETS) and the French Energy Saving Certificates (EMSP), the use of low-carbon fuels like green hydrogen is financially incentivised. These mechanisms can significantly offset the cost of transition, reinforcing the business case for decarbonisation.

Take the Next Step Toward Decarbonising Your Glass Operations

Green hydrogen is a proven, immediately deployable solution for high-temperature processes in the glass industry. With no need to retrofit furnaces, only minimal burner replacement and minimal adaptation to combustion control systems, implementation is both straightforward and low disruption.

Combined with the availability of carbon-reduction incentives (such as ETS and EMSP) and multiple viable combustion configurations—including pure hydrogen, hydrogen-natural gas blends, and oxy-combustion—green hydrogen offers a technically robust and future-ready alternative to fossil fuels.

Lhyfe’s team of hydrogen integration experts is ready to support you in evaluating, designing, and deploying a tailored hydrogen solution that aligns with your process requirements and regulatory goals.

Contact our technical team today to assess the feasibility of green hydrogen for your site and begin your transition toward low-carbon glass manufacturing.

Related content you might be interested in

Article

Published the 27/07/2022

Industry decarbonisation: the importance of renewable hydrogen

Although there has been much talk recently about hydrogen vehicles – as they offer a real solution for carbon-free mobility – hydrogen has nonetheless been used in industry for decades, such as to fuel furnaces, in chemical processes and refining, and even to launch rockets into space.

Press release

Lhyfe and Exogen partner to scale up green hydrogen production for industrial steam, mobility, and district heating applications

Lhyfe to build and operate green hydrogen production facilities for the combined product offering, opening large new markets for growth in industrial steam and district heating.